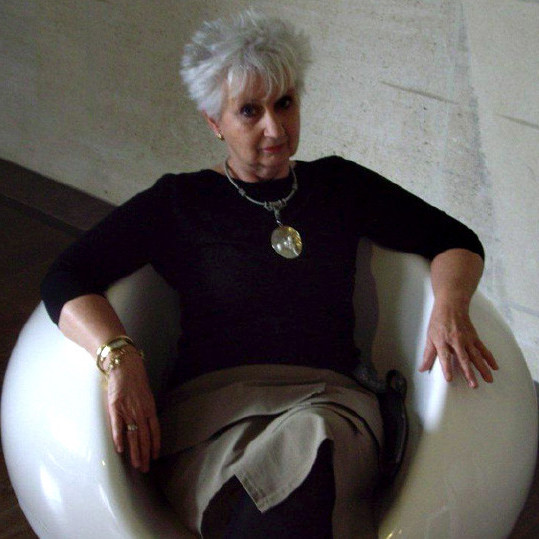

Clare Bigger Sculptor - Lancashire, UK

Can you tell us about your sculpture the Irish Elk?

‘Irish Elk’

The commission

The “Irish Elk” was commissioned by Mourne Heritage Trust, Warrenpoint, Northern Ireland. This was a collaboration with Irish Artist Paul Regan, who conceived the idea and managed the project. I designed and manufactured the Elk at my workshop in England and then shipped it to Northern Ireland once completed. It arrived in Warrenpoint by ferry

The time it takes to bring a huge project like this together.

On average the whole process from conception to installation take about 1 year or so. The actual build time takes 3 – 4 months.

How you work in collaboration with other sculptors on projects?

It is unusual for me to work with another artist. Paul Regan and I worked well together sharing relevant parts of the project. Together we also offered a community art workshop in the area as part of a community engagement plan.

How much help do you require to produce large scale pieces?

Sculptures up to the size of the Irish Elk I can build single handed with some outside help with the structural welding. I do not like to hand over the fabrication of my sculptures to someone else preferring instead to do as much as possible myself. However larger pieces are a two man job and for these projects I move into the much bigger premises of Trapp Forge which has overhead lifting gear and work with one of the blacksmiths. This works really well for me in that it allows me to preserve the feel of the original design and ensure that nothing is lost in the scaling up of the sculpture. Having made 20 or so large commissions at Trapp Forge, they are used to me completely rehashing something that they thought was finished the day before!

Clare with ‘Irish Elk’

Can you discuss the different space – studio, foundries you need for your work?

I have a small studio at Trapp Forge, in which I make all of the smaller pieces. Trapp Forge is a lovely place, set in the rolling landscape of Lancashire. Next door to my studio is a local blacksmiths forge which does blacksmithing and steel fabrication.

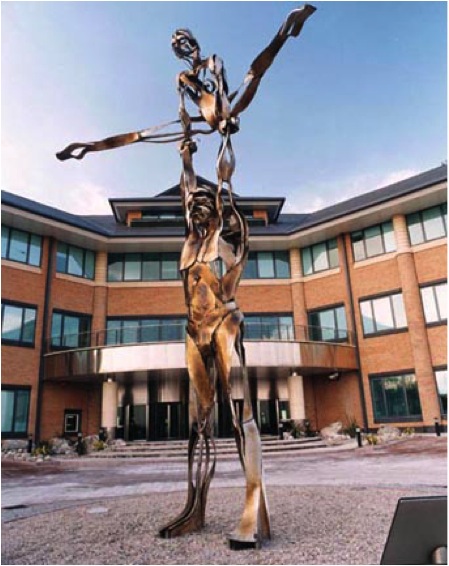

Can you discuss the commission of ‘Climbing to New Heights’ and your thoughts on the importance of sculpture in public places?

“Climbing to new heights” was commissioned by Wigan Council. It is located on a new roundabout which is part of a business park development. It acts as a landmark for the local area, giving a pride of place. It is for these reasons that I think art is important in public places. Also, providing easy access to art – you can see it for free without having to go into a museum or art gallery.

‘Climbing to New Heights’

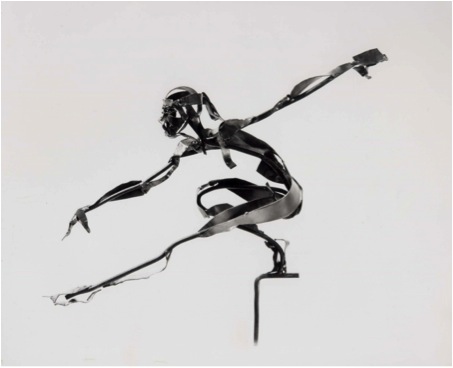

Can you tell us about ‘Gymnast’?

‘Gymnast’

This relatively small piece stands 12” high and is made of mild steel which has been lacquered. It was quite an early piece. I have always been inspired by sports people and how they can train their bodies and minds to perform such amazing feats. When I was young my heroes were people like Olga Korbut and Daley Thompson.

The human body plays a large part in your work can you discuss how you can achieve such movement out of metal?

The form is loosely based on the musculature of the human body. I pick and choose which muscles I think will enhance the feeling of movement and create a flow within the body.

‘The Champions’

How forgiving is the material you use to the bending and manipulation you place on it?

When I first started making sculptures at Art College I was often frustrated by the fact that sculptures made out of clay and plaster collapsed. The metal work technician suggested using steel as an armature. When I tried out steel I knew that I had found the perfect medium for what I was trying to achieve. I could cantilever off balance sculptures using the smallest of supports. I use pliers, forks (long handled levers) and vices to help me bend the metal without having to use heat.

You have also made smaller scale work that is similar to larger pieces. Can you discuss this in relationship to cats and dogs?

I have recently started making smaller cats and dogs. I love making these pieces which are so immediate. The lighter material means that it’s like sketching in metal. A quick twist here and a bend there can be done effortlessly.

‘Figaro’

‘Petite Psipsi’

‘Flycatcher’’

When making larger pieces, I usually start by making a maquette and scale up from that. I try to retain the flow and spontaneity of the original piece.

When and how do you decide to use stainless steel or mild steel?

I tend to use stainless steel for all my pieces now. It can be placed outside without any need for extra treatment and also gives a wider colour range.

Can you explain the difference between the two steels and the weathering effects it has on the finish piece?

Mild steel rusts unless it has been powder coated or lacquered. Stainless steel doesn’t rust and is perfect for outdoor pieces.

How restricted are you by the available sizes of the steel available and also the cost of steel?

Gibfield Park framework

Stainless steel is much more expensive than mild steel, but requires far less after care. I’m not particularly restricted by availability of sizes of steel. I’m more restricted by what I can and can’t do at the Forge. For example, I can roll and bend tube with a hydraulic pipe bender but only up to 2”diameter. Larger pipe has to be rolled elsewhere but they will only roll in one plane. To achieve a 3D effect I have to cut the pipe, twist it and then weld it up again.

I am also limited by my strength. I can manipulate plate up to 4mm thick using levers but after that heat or hydraulics would have to be used.

When you are making a piece, what are some of the technical decisions you have to make both for the studio space and the final commissioning of the piece?

Installing Gibfield

The overall height of the piece determines whether it can be built indoors or has to be fabricated inside on the floor and then put together outside. Because of the nature of my designs, I prefer to build them upright. This allows me to see them from every angle and make adjustments throughout the process.

Installing Gibfield

Transport to site is also a major consideration. There are height and width restrictions so most sculptures have to come apart and be bolted or welded together again on site. Also we have to give a thought to the way the pieces will be craned into place.

Transporting ‘Climbing to New Heights’

A structural engineer will always be involved in the bigger projects and will advise us on material sizes to ensure strength and longevity of the structure.

How did a nice girl like you come into the huge steel world?

When I first left Art College and was trying to make ends meet I worked for someone who was building polystyrene sets for the film and TV industry. It was really exciting work, very varied and often on a huge scale. Maybe this gave me a belief in my abilities to do things on a larger scale. Then in 1995 I was asked to make some smaller sculptures for the newly built head office of Birmingham Midshires Building Society. The gallery that I was dealing with asked whether I could also make a larger piece to be sited outside the offices. It was a challenge but I felt that I could do it. It was a steep learning curve but I had the help of an excellent structural engineer who gave me a lot of good advice. On that first piece I enlisted help from my dad and brother. Over the years and the many projects, I have learnt a lot from the blacksmiths and steel fabricators at Trapp Forge. Apart from blacksmithing techniques, I have picked up a few good tricks of the trade for manipulating sheet metal and pipework as one or two of the fabricators had previously worked in industry making tankers.

Contact Details:

www.clarebigger.com

Email: clare@clarebigger.com

Clare Bigger, Lancashire, UK

Interview by Deborah Blakeley, August, 2013

Think a colleague or friend could benefit from this interview?

Knowledge is one of the biggest assets in any business. So why not forward this on to your friends and colleagues so they too can start taking advantage of the insightful information the artist has given?

Other artists you may be interested in: